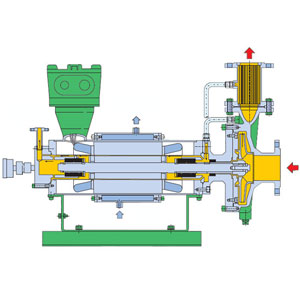

新品推荐

| 地 址: | 上海市奉贤区沪杭公路1359号1幢一层 |

| 邮 编: | 201400 |

| 电 话: | 021-67103258转接各部 |

| 传 真: | 021-67103250 |

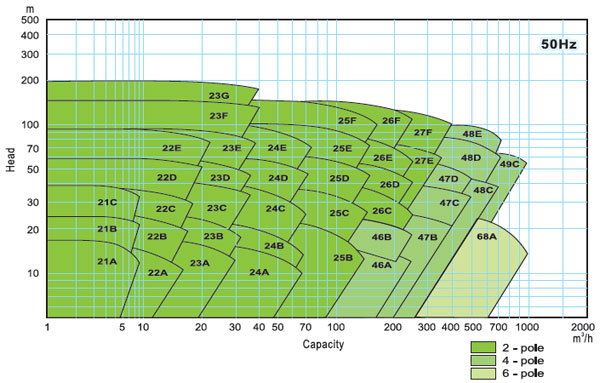

性能曲线

日机装屏蔽泵输送介质的主要业绩

| 酸类 | 硫酸,硝酸,混合酸,磷酸,氢氰酸,铬酸,醋酸,乙二酸,乳酸,甲基丙烯酸, 氯磺酸,脂肪酸,硼酸 |

| 盐类 | 氯化钙,氯化钠,碳酸钠,硫酸铵,硫化硫酸钠,氰化钠,重铬酸钾,氯化锂, 亚硫酸铵,次氯酸钠,氯酸钠,溴化锂 |

| 碱类 | 苛性钠,苛性钾,氨水 |

| 酯 | 醋酸甲酯,醋酸乙酯,醋酸戊酯,甲基丙烯酸甲酯 |

| 芳烃类 | 苯,甲苯,二甲苯,苯酚,萘,二氯代苯,甲酚,甲基萘,烷基苯 |

| 碳氢化合物 | 丁烷,己烷,丙烷,乙烯,丙烯,环己烷 |

| 醇类 | 甲醇,乙醇,丁醇,异丙醇,辛醇,甘油,乙二醇,丙二醇 |

| 氧基化合物及醚类 | 甲醛,乙醛,苯甲醛,甲醚,乙醚,丙酮 |

| 卤化物 | 液氯,四氯化碳,三氯乙烯,氯丙烯,无水氟化氢,二氯甲烷,氯甲烷,四氯化钛, 四氯化硅,三氯氧化磷,三氯化磷,二氯乙烯,二氯丙烯,氯仿,三氯甲硅烷,氯化铝 |

| 氮硫化合物 | 二硫化碳,无水二氧化硫,肼,苯胺,丙烯酸铵,乙胺 |

| 冷冻剂 | 氟利昂,干冰,液态甲烷,液氨 |

| 油类 | 石油衍生产品,变压器油,食用油,润滑油 |

| 热媒和冷媒 | 道氏热载体和其他热媒,溴化锂,氯甲烷和其他冷媒 |

| 水 | 纯水。热水,海水,废水和其他类水 |

| 单体和化合物 | 聚氯乙烯,聚乙烯醇,苯乙烯,己内酰胺,丁二烯,乙烯醚,氯丁橡胶,乙腈 |

| 其他 | 水银,四乙基铅,三乙基烷,硅烷,过氧化氢,可塑剂,显像液明胶,清洁剂,糖液 |

| Acids | Sulphuric acid,Nitric acid,Mixed acid,Phosphoric acid,Hydrocyanic acid,Chromic acid,Acetic acid, Oxalic acid,Lactic acid,Methacry~c acid,Cblomsulfomc acid,Fatty acid,Boric acid |

| Salts | Calcium chloride,Sodium chloride,Sodium carbonate,Ammonium sulfate,Hypo,Sodium Cyanide, Potassium bickromata,Lithium chloride,Ammonium sulphite,Sodium hypochlorita,Sodium chlorate, Lithium bromide > |

| Alkalis | Caustic soda Caustic potash Ammoia water |

| Esters | Methyl aeetata,Ethyl acetate,Amyl,acetate,Methyl mcthacrylate |

| Axomatic Compounds | Benzene,Toluene,Xylean,Phenol,Naphthalene,Dichlorobenzean,Cresol, M~thyl naphthalene, Alkylbenzene |

| Hythocarbons | Butane,Henene,Propane,Propylene,Ethylene,cyclohexane |

| Alcohols | Methanol,Ethanol,Butanol,Isopropyl alcohol,Octyl alcohol,Glycerine,Glycol,Propylene glycol |

| Oxo-Compounds and Etheas | Formaldehyde,aldehyde,Benzaldehyde,Methyl ethers,ethyl ether,Acetone |

| Halogenides | Carbon,telracldoride,Trichl~thylene,Allyl chloride,Phosgene,Mqmd chloride,Anhydrous hydrogen fluoride,Methylene chloride,M~thyl chloride,Titanium tetrachloride,Silicon tetrachloride,Phosphcens oxychloridc,Phosphorus trichloride, Ethylene dichloride(EDC),Propylene dichloride, Tetrachloroethylene,Chloroform,Smcochloroform,Aluminum chloride

|

| Nitrogen and Sulfur Compounds | Carbon disulfide,Anhydrous ssulfur dioxide,Hydrazine,Anthne,Acrylamide,Ethylamine |

| Cryogenic Liquids | Freon,Liquid carbon dioxide,Liquid methane,Liquid ammonia |

| Oils | Petroleum related products,Transformer oil ,Edibleoil,Lubricants |

| Heat and Cool Medium | Dowthenn,Mobiltherm and other beat transfer media,Lithium bromide,Methyl chloride and other coolants |

| Watar | Distillate pure water,Hot water,Sea water,and other types of water |

| Monomers and compound | PVC,PVA,Styrene,Caprolactam,Butadiene,Wmyl ether,Neoprene,Acetonitrile |

| Other | Mercury,Tetraethyl lead,Triethyl,aluminum silaue,Methyl silane,Hydrogenperoxide,Plasficizars, Developers,Gehtine,Detergents,Syrups,Paints |

型号表示/规格范围

H N 21A - A1 C A C - 01 D1 X X

(1) (2) (3)- (4) (5) (6) (7)- (8) (9) (10) (11)

| 编号 | 分类 | 内容 | ||||||||||||

| (1) | 形式 | H-横行,L-管线性,B-电机在上立型, T-泵体在上立型,D-自吸横型,S-液中型 |

||||||||||||

| (2) | 结构 | N-普通型,V-高粘度型, T-高温型(带隔热盘), S-泥浆分离型(带密封杯), M-泥浆分离型(带机械密封), G-泥浆分离型(带气体密封),Q-反向环流性, R-反向环流型(带连接器),B-高熔点型, C-简易高熔点型,W-普通外循环型, X-超耐热型(最高温度max。350℃(662°F)) |

||||||||||||

| (3) | 泵的编号 | 21A/B/C,22A/B/C/D/E,23A/B/C/D/E/F/G,24A/B/C/D/E/F, 25B/C/D/E/F,26C/D/E/F,27E/F,46A/B, 47B/C/D,48C/D/E,49C,X12/22/32/42 |

||||||||||||

| (4) | 电机规 格编号 |

A1-A3,B1-B3,C1-C4,D1-D3,F1-F4,G1-G3,H1-H2,J1-J4, K1-K4,A5,B5,C5,F5,G5 |

||||||||||||

| (5) | 电机绝缘 | H-H种绝缘,C-C种绝缘 | ||||||||||||

| (6) | 电机电 压编号 |

|

||||||||||||

| (7) | 电机防 爆等级 |

A-dⅡBT1,B-dⅡBT2,C-dⅡBT3,D-dⅡBT4, S-dⅡCT3,J-dⅡCT4,T-TE |

||||||||||||

| (8) | 最大容 许压力 |

01-1.0MPa(150psig),02-2.0MPa(150psig), |

||||||||||||

| (9) | 材质构 成编号 |

C1-SUS304/SCS13,C2-SUS304/SCS19, D1-SUS316/SCS14,D2-SUS316L/SCS16, E-CA20(Alloy20),G2-HastelloyC |

||||||||||||

| (10) | 夹套和热 交换器 (对电机) |

X-无,J-带可拆卸夹套,K-带可拆卸夹套,夹套和定子筒材质为SUS304,L-带焊接夹套,材质为钢,M-带焊接夹套,夹套和定子筒材质为SUS304,N-带焊接夹套,泵液冷却,材质同泵C-带热交换器,D-带热交换器,热交换器和定子筒材质为SUS304,E-外置的热交换器 | ||||||||||||

| (11) | 夹套和热 交换器 (泵壳和后轴承座) |

X-无,P-泵壳有焊接夹套,Q-泵壳有铸件夹套,R-泵壳有铸件夹套,后轴承座有焊接夹套,S-泵壳和后轴承座有焊接夹套 |

| NO | Categories | Content | |||||||||||||

| (1) | Model | H-Horizontal, L-In-line, B-Motor top T-Purnp top, D-Self-priming, S-Submerged |

|||||||||||||

| (2) | Construction | N-Basic, V-High viscous, T-High temperature with thermal isolation spacer, S-Slurry liquid with seal ring, M-Slurryo liquid with mechanical seal, G-Slurry liquid with gas seal, Q-Reverse circulation, R-Reverse circulation with adapter, B-high melting, C-high melting(simple type), W-Basic external circulation, X-No cooled high temperature, liquid temprtstutr, liquid temperature max350°C(662°F) |

|||||||||||||

| (3) | Pump model | 21A/B/C, 22A/B/C/D/E, 23A/B/C/D/E/F/G, 24A/B/C/D/E/F, 25B/C/D/E/F, 26C/D/E/F, 27E/F, 46A/B, 47B/C/D, 48C/D/E,49C, X12/22/32/42 | |||||||||||||

| (4) | Motor size | A1-A3, B1-B3, C1-C4, D1-D3, F1-F4, G1-G3, H1-H2, J1-J4,K1-K4,A5,B5,C5,F5,G5 | |||||||||||||

| (5) | Moror insulaton | H-H class, C-C class | |||||||||||||

| (6) | Power supply voltage |

|

|||||||||||||

| (7) | Explosion-proofcode | A-dIIBT1, B-dIIBT2, C-dIIBT4, S-dIICT3, J-dIICT4 T-TE | |||||||||||||

| (8) | Maximum allowable working pressure | 01-1.0MPa(150psig), 02-2.0MPa(300psig), 03-3.0MPa, 04-4.0MPa(600psig) |

|||||||||||||

| (9) | Materials code | C1-SUS304/SCS13, C2-SUS304/SCS19, D1-SUS316/SCS14, D2-SUS316L/SCS16, E-CA20(Alloy20), G2-HastelloyC | |||||||||||||

| (10) | Jacket and Heat Exchanger forMotor | X-Non,J-with mount type jacket, K-with mount type jacket, jacket and stator band material SUS304, L-welded typc jackct matcrial steel, M-welded type jacket, jacket,and stator band material SUS304 N-welded jacket cooling with pump un liquid, material same as pump, C-with heat exchanger, D-with heat exchangermhe, heat exchanger and stator band material SUS304, E-with separated heat cxchanger |

|||||||||||||

| (11) | Jacket and Heat Exhanger for Casing and Rear Bearing Housing | X-Non, P-with welded type jacket on casing, Q-with casing type jacket on casing, R-with casing type jacket on casing and welded type jacket on rear bearing bousing, S-with weded type jacket on casing and rear bearing bousing |

日机装牌屏蔽泵的选型范围

| 标准 | 次标准 | |

| 最大流量 Max.Capacity |

780m3/h(3,430gpm) | 1200m3/h(3430gpm) |

| 最大扬程 Max.Head |

300m(984ft) | 500m(1970ft) |

| 工作液温度 Flttid.Temp.Range |

-60 to 350℃(-76 to 662°F) | -200 to 450℃(-328 to 842°F) |

| 比重 SpealficGravityRange |

0.3 to 2.0 | Max.13.6 |

| 最大粘度 Max.viscosiW |

200mPas(200cP) | 500mPas(500cP) |

| 最大工作压力 Max.Working Pressure |

4MPa(600psig) | 80MPa(1200psig) |

| 按液部分材质 LiqmdEndMaterial |

SUS316,SUS316L,SUS3.4 | ·合金20 Alloy 20 ·镍合金C/B HastelloyC/B ·钛 Titamium ·钛·锆等 ZJreonhlmete ect. |

| 电机功率范围 MotorPowerRange |

0.4 to 132kw |

此标准设计需技术咨询

The standard design technology consulting